|

|

|

|

|

Basically all the breeds of Azerbaijan sheep are shorn twice a year: Firstly in spring - generally in April (so that sheep don't get overheated in the summer), and then in autumn. Lezgi sheep are shorn for the second time a year, in the end of summer (August) or in September. Exceptionally, Mazekh is shorn only once a year. Karabagh and Garadolag rams are also shorn once a year, but their ewes are shorn twice a year. Lamb which is born in March are sheared in summer, either in July or in August. Mostly spring wool has been used for rug weaving in all the provinces of Azerbaijan. Exceptionally, in Kazak (Gazakh) region autumn wool has been the main source for rugs. The thicker, longer spring wool is better not only because of its length and strength (because of passed winter), but also because it "takes the dye" more evenly than summer wool. |

|

|

|

Time of spring

shearing changes from country to country. For example, Qashqay

tribesmen start shearing

from the 20th of February to the 20th of May, while most Azerbaijanis start in

April. This is mostly due to the climate differences. The best time for wool

shearing is a little while before migration of tribe or villagers to cold

region, so sheep get lighter, owing to wool cutting. |

|

Shearing process is done in this way: A sheep is caught by the shearer. Most villagers in Azerbaijan shear their own sheep manually with scissors or hand blades, while electric shears or shearing machines are used mostly in the cities. Shearing doesn't hurt a sheep. It's just like getting a haircut. The wool is removed by following an efficient set of movements. The shearer begins by removing the coarse wool over the sheep's belly, which is separated from the main fleece while the sheep is still being shorn. A good shearer typically removes a fleece without badly marking or cutting the sheep in 15 minutes, depending on the size and condition of the sheep. For a medium sized carpet the wool of a few sheep is needed. The amount of wool produced by one sheep varies from 1 to 3 kg (2 to 6 lbs). Small sized rug, such as the one with the size of 1 square meter, requires about 3 kg of handspun wool. |

|

|

|

It takes up to six weeks for the fleece to regrow sufficiently to provide effective insulation. Sheared sheep also require more food to maintain their body temperature, if the weather is cold. Sheep grow wool continuously. If they are not sheared at least once per year they can become very uncomfortable and stressed, especially when it is hot and humid. The wool will become matted and more difficult to shear if it is not removed in a timely basis. |

|

|

|

The first thing that must be done right after shearing is sorting the wool. Wool from ewes, rams and lambs must be sorted from each other and kept separately. Ewe's wool during lactation period is in its coarsest quality. Different quality of wool is used for wefts, warps and pile. Therefore, while sorting wool, the factors such as the length of fibers and wool's ability of absorbing dyes etc. should be taken into consideration. Wool which is going to be the source of the yarns for pile should be supple, resilient and soft. The quality of wool varies not only due to the different type of breeds, but it also depends on the geographic location of animals, climatic conditions of the region, the season of shearing, the quality and composition of fodder etc. |

|

|

|

The fleeces are spread out on tables (or ground), placed preferably in a well lit room, for the sorters who work at the tables must have the best lighting conditions in distinguishing the various kinds or qualities of wool in a fleece. The top of the table is usually made of wire netting to permit dust, sand, and other dirt to fall through when loosened from the wool. |

|

Inferior grades are obtained from the withers, e, saddle, f, croup, g, throat and breast, h, the top of the neck, i, thighs, k, root of tail and breech, l, head, m, and skins, o.

|

We have seen that there are numerous kinds of wool. Every fleece comprises several kinds of wool. The wool is not uniform over the entire body of the sheep. Some parts are longer than others, some are finer, some cleaner. The fleece, then, must be duly divided into parts in order to get the uniform wool desired. The best wool comes from the sides of the sheep, the next best from the back and thighs, that from the belly and throat is inferior, and the poorest wool comes from the breech and lower part of the legs. In some cases the fleece is divided into more than these four classes of wool. The job of sorting wool is not particularly pleasing or cleanly. The wool is always greasy and often very dirty, and not infrequently filled with sharp thistles, thorns, and burrs. The wool sorter grows accustomed to this, his hands finally growing so hard that the ordinary impurities in the wool have no effect on them. |

| After the wool is sorted, it must be washed. Some of the foreign substances in the raw wool can be removed simply by washing in water, but the grease sometimes requires a solvent such as soap. Grease content of wool is important: If too much lanolin is left in the wool it will repel the dye in places, resulting in a mottled effect, yet a small amount of it makes spinning easier and deepens the colors. |

|

|

|

Washing, a very laborious process, has been normally carried out on the bank of a river by villagers. In some districts, rain water has been used. The wool is sometimes washed in large vats or tanks. Wool firstly is washed in warm water and then it is again washed in cold water. The temperature of the water is a matter of importance. If very hot water is used, the wool will lose its fluffiness; if the water is too cold, it is hard to wash out the grease. Naturally the temperature should be somewhat adjusted to the kind of wool, to its fineness, and to the amount of dirt therein. |

|

Traditionally, two or three persons are involved. The wool is spread over a large piece of rock, watered and beaten with a heavy stick until absolutely clear water runs from under it. Only then wool is regarded as properly washed. After wool is properly washed, it is spread over the rocks, bushes or palazes at the riverbank. Shearing and washing are the only processes performed outside the house.

|

|

| After wool is dry, it must be beaten with a chubug. Chubug is a special, thin wooden stick which generally made of the branch of hazelnut tree. |

|

|

The next step is carding.

Carding

is done with a special tool which is called yun darağı. (Comb for wool)

Carding is carried out as follows: wool is fitted onto the comb's teeth

and torn by hands into two parts, then the two bunches of wool were put

together again and the operation is repeated until

all the fibers in a bunch align in the same

direction more or less.

This straightens and smoothes the fibers to prepare

them for spinning. Because of the difficulty of this chore, close relatives and neighbors are usually involved. This mutual help is called imaji. |

|

|

|

|

|

|

|

Primitive domestic methods of yarn spinning

are the same throughout Azerbaijan. Two different kinds of tools have been

used to spin the wool into thread:

1) "iy"[eey] or "teshi" which means a spindle or drop spindle

2)"jahra", which means a spinning wheel

|

|

|

1) Spinning with Iy (iğ) or Tesh - Spindle

|

Iy -

drop spindle is a wooden spike (25-30 cm) weighted at one end with a

circular whorl; it may have an optional hook at either end of the spike.

Perhaps, spindle is the most ancient spinning tool. Spindles or parts of

them have been found in very old archaeological sites; they may represent

one of the earliest pieces of technology available to humankind.

Working with spindle: The first step is pulling fibers out

of the prepared lock. Pulling just a few fibers at a time makes a very

thin yarn; drafting many fibers makes a thick yarn. Twisting the drafted

fibers makes yarn. Twist holds the fibers together so they donít

slip apart or rub loose; one of the spinnerís skills is determining the

appropriate amount of twist for a given yarn. After pulling and twisting a

length of yarn, it must be wind it onto spindle by hand, then start

drafting and twisting more yarn. When one batch of fiber is finished

spinning , a join must be made by splicing on a new supply. A careful join

is invisible in the finished yarn.

And incorrectly spun of yarns can easily break while

stretching the warps or beating the wefts. Yarns that are spun to uneven

thickness can cause the pattern to distort.

Turning the wheel (or spindle) one way gives us Z twist yarn. By turning it the other way we get S twist yarn. By convention, most spinners turn the wheel clockwise (Z) to make yarn from loose fiber, but the only rule is that if you start spinning in a given direction you need to keep going that way until youíve finished with that spindle.

When spinner turns loose fiber into yarn, she makes a singles yarn (a single strand), with the fibers all twisted in the same direction. Singles yarn can be finished and used as is, but spinners often take an extra step, twisting two or more strands of singles together to make plied yarn, which is usually stronger, more uniform, and easier to handle than singles. The simplest plied yarn twists two singles together in the opposite direction to their original spinning (Z singles, S plied). |

2) Spinning with jahra (spinning wheel)

|

|

|

|

|

|

|

|

|

|

|

The first stage in mechanizing the process is to

mount the spindle horizontally in bearings so that it could be rotated by

a cord encircling a hand-driven wheel. The fiber is held in the left hand

and the wheel slowly turned with the right. Holding the fiber at an angle

to the spindle produces the necessary yarn. Women as old as 90 do the hand-spinning, some with drop spindles and others with spinning wheels.

|

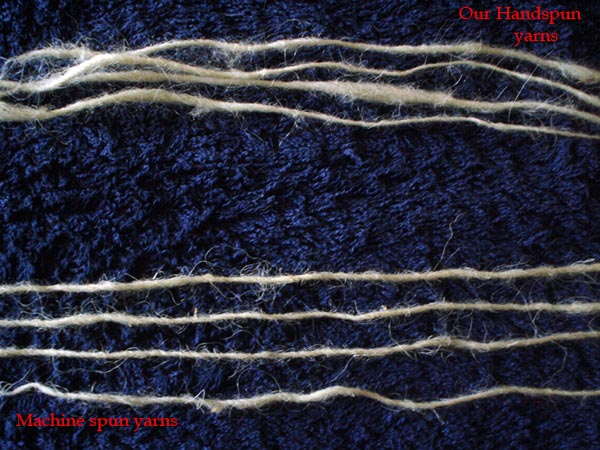

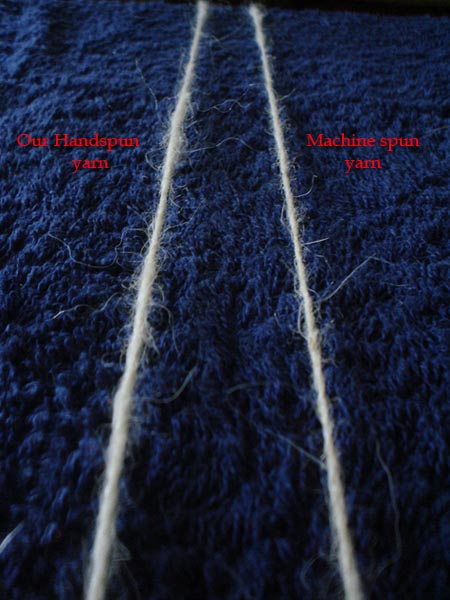

Advantages of handspun yarn to machine spun yarn

- Hand-spinning is superior to machine spinning, because it produces a relatively loose yarn that both exposes more surface to the dye and knots properly.

- Handspun yarn is not of uniform diameter. Therefore, while applying natural dyes to handspun wool, the dye is diffused through the yarn unevenly. And this cause the yarn reflecting 3D effects of natural dyes perfectly. On the other hand, the evenness of machine spun yarn creates monochromatic colors, even if natural dyes apply to it.

- Quality and fat amount of

handspun wool cause the colors to look different according to the direction

of the pile. This feature is not distinguishable at all in the rugs which

are made of machine-spun yarns.

-

Pile which are made of handspun wool is always pleasurable to touch and

feel, while the same thing can not be said about machine spun wool.

-

Most of valuable antique rugs are made of hand spun wool.

a) Take

a piece of machine spun yarn. Pinch and pull the edge of the yarn slightly.

The fibers of the yarn will break into tiny pieces easily. While the same

test is done with handspun yarn, long pieces of fibers will come out of the

spun yarn.

b)

Take a bowl and fill it with water. Dip a piece of machine spun yarn into

the water, take it out and stretch it slightly. Machine spun yarn will break

into two pieces quickly and easily. Now dip handspun yarn into the water.

Apply the same amount of force to

stretch the yarn. Handspun yarn will hardly break or will not break at all.

Other Benefits of Pure Hand-Spun Wool Rugs Pure hand-spun wool has fabulous naturally

occurring properties that make it a necessity for your health and home. When we

speak of authentic collectible wool Oriental rugs, these are always of hand-spun

pure wool (from a living animal) that has neither been chemically washed, nor

mixed with synthetic polymers, nor spun by machine. All these processes destroy

the physical properties of pure hand-spun wool that make it so beneficial to

your health and home. Here are some benefits of pure wool: 1) Hypoallergenic Pure wool rugs are natural, healthy

products that are non-allergenic, which is beneficial for those of you who

suffer from allergies or asthma. Because they are not mixed with synthetics,

pure wool rugs are non-toxic. Unlike synthetic wall-to-wall carpeting with its

chemical sealants and adhesives, no toxic gasses are emitted from pure wool

rugs. The naturally inherent lanolin coating on the wool fibers also acts as a

repellent to dust mites, leaving them no home in the pure wool rug. Pure wool is also considered a living

thing. It remarkably is able to release moisture it attracts from the air back

into the atmosphere, making it resilient to mold or mildew, and reducing static

electricity. This natural process also enables pure wool to purify indoor air of

common household pollutants, by trapping them inside the wool fiber. Such

household contaminants include sulfur dioxide, nitrogen dioxide, and

formaldehyde gasses that are emitted from common chemical-based household

products, such as cleaners and synthetic carpets. Exposure to these pollutants

is being reported as the cause of many illnesses, including neurological and

respiratory disorders. Doctors are prescribing natural wool products for

patients suffering from Multiple Chemical Sensitivity (MCS) and other

environmental illnesses. 2) Fire Resistant The high moisture and protein content of pure wool makes it naturally

resistant to fire. Pure wool is self-extinguishable. This means that even if you

drop a burning match on the rug, the burnt fibers will be only those that

touched the flame, and can be brushed away. 3) Stain Resistant Unlike machine-made synthetic rugs, hand-woven pure wool rugs do not

"hold" dirt. The natural construction of the wool fibers keeps dirt on

the fibers' surface and prevents it from being trapped inside the core. This

makes vacuuming very easy. The absence of a "backing" on a hand-woven

pure wool rug also allows dirt to pass through to the floor over time, thus

preserving the life of the rug. The protective layer of lanolin on the pure wool fibers makes these rugs

stain resistant. Liquid spills are repelled to the upper surface of the wool,

and can be blotted up with immediate treatment. 4) Durable Pure hand-spun wool is the preferred fiber in Oriental rugs that will receive

frequent floor use. Such rugs will last you at least a lifetime, and can be

handed down generation to generation with proper

care.

Two simple tests to check the quality of handspun yarn vs. machine spun

one:

Here is the difference between our handspun wool and the machine spun

wool which is used in the market for the production of carpets:

Copyright © Azerbaijan Rugs 2004-2019

E-mail:

vd@azerbaijanrugs.com

E-mail:

ra@azerbaijanrugs.com

Tel: +994 50 380 88 78

(Baku, Azerbaijan)

Tel: 415.690.7735 (San Francisco, USA)